Plan and Care

Problem 1

- To cipher to top out operative temperature in this room in August, some assumes are made before computation:

- The operative temperature in bordering suites is equal to that for the faculty under consideration and hence heat freshness occur merely through the outside window-wall ;

- The window will be unfastened during the twenty-four hours and near at dark ;

- The thermic transmission of the window frame is equal to that of the glass ;

- There are no internal blinds, therefor the solar addition to the air node is zero ( Sa =0 )

- Harmonizing to the equation ( 5.42 ) , this computation will be divided into three parts. First, happen out the average operative temperature. Second, find out the swing in operative temperature. And happen out the peak temperature in the concluding.

- Calculation:

Area:

External wall = 3.08m2, Internal wall = 40.88m2, Internal floor = 19.8m2

Ceiling ( intermediate floor ) = 19.8m2,

Glazing ( include. frame ) = 7.0m2

Volume of room = 55.44m3

Summed values:

Summed country = 90.56m2

= 90.56m2

Summed U Value = 22.1/WK-1

= 22.1/WK-1

Summed U Value = 321.2/WK-1

= 321.2/WK-1

First portion – Mean operative temperature:

Solar Gain through glazing ( Table 5.7 ) :

= 0.62 ten 177 ten 6.3

= 691.36W

Internal heat addition:

= ( 792 + 1280 + 1584 ) / 24

=152.33W

Fabric heat addition ( Table 2.34 ( H ) ) :

= ( 3.08 x 0.49 ten 26.9 ) + ( 7 x 2.94 ten 19.8 )

= 448.08W

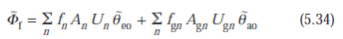

Entire additions to environmental node:

= 691.36 + 152.33 + 448.08

= 1291.8W

Entire addition to air node:

= 0 + ( 55.4 x 19.8 )

= 1097.7W

Room airing conductance ( Table 5.2 ) :

=1/3 x 3 x 55.44

=55.44WK-1

Thermal response factor for the room:

= ( 321.2 + 55.44 ) / ( 22.1 + 55.44 )

= 4.9

Room conductance rectification factor ;

= 3 [ 55.44 + ( 6 x 90.56 ) ] / 22.1 + ( 18 X 90.56 )

= 1.09

Mean operative temperature at centre of room:

= [ 1097.7 + ( 1.09 x 1291.8 ) ] / [ 55.44 + ( 1.09 x 22.1 ) ]

= 31.51K

Second Part- Swing in operative temperature:

Swinging in solar addition ( Table 2.30 and Table 5.7 ) :

= 0.44 ten 6.3 x ( 603 – 177 )

= 1180.9W

Swinging in structural addition ( Table 2.34 ( H ) , and given clip slowdown factor ( 9.5h ) ) ;

= [ ( 0.18 x 3.08 ten 0.49 ) ten ( 11.7 – 26.9 ) ] + [ ( 1 x 7 ten 2.94 ) ten ( 24.8 – 19.8 ) ]

= 98.77W

Swinging in internal addition ;

= [ ( 2 x 80 ) + ( 10 x 19.8 ) ] – 152.33

= 205.67W

Swinging in airing heat addition:

= 55.44 tens ( 24.8 – 19.8 )

= 277.2W

Entire swing in heat addition to environmental node:

= 1180.9 + 98.77 + 205.67

= 1485.3W

Entire swing in heat addition to air node:

= 0 + 227.30

= 227.30W

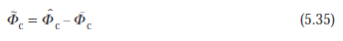

Mean-to-peak swing in operative temperature

Room entree factor with regard to operative temperature ;

= 3 [ 55.44 + ( 6 x 90.56 ) ] / [ 321.2 + ( 18 x 90.56 ) ]

= 0.92

The swing in operative temperature at 12:30:

( at 12:30 ) = [ 277.2 + ( 0.92 x 1485.3 ) ] / [ 55.44 + ( 0.92 x 321.2 ) ]

= 4.68K

Concluding Part:

Peak internal operative temperature:

= 31.51 + 4.68

= 36.2°C

As the consequence, the temperature is excessively high in the office infinite, some issues of shadowing or chilling should be required to cut down the hazard of overheat.

Problem 2

2a )

During undertaking handover, the operational hazard direction rhythm starts with the first execution processs by making the hazard stock list through hazard designation and hazard appraisal.

Get downing with hazard designation and appraisal, the better the hazard appraisal and the hazard information gathered is structured ; the more successful will be the hereafter go oning reassessment procedure. Good consequences for hazard rating are achieved if unit caputs and hazard or procedure experts agree on the rating of the hazard.

Then, hazard extenuation and control system is carried out in position to adequately measuring the impact of an identified hazard on the organization’s concern, one has to see bing controls and extenuating steps that already cut down the likeliness or badness of the hazard scenario identified. A hazard mitigating step is normally a erstwhile step for which an nidation day of the month and a responsible individual are defined. Risk scenario, extenuation step, control, and loss event aid to maintain path of the execution stairss. These consequences in improved transparence, efficiency and informations unity compared to the widespread solutions that typically create jobs with respect to user entree rights, informations unity and confidentiality.

Followed by hazard extenuation and control system is risk commanding and describing. The end of the hazard direction procedure is to maintain identified hazards in line with the hazard policy and hazard scheme approved by the Board of Directors and the executive squad. This procedure could guarantee bing controls are really performed and freshly approved hazard extenuating steps are implemented as planned.

Last, followed by the above stairss of operational hazard direction procedures, simple hazard collection and consolidation methods can be introduced.

Grouping hazards by classs to look for worst-case hazard scenarios, consolidating hazards across concern units and measuring dependences, correlativity or variegation potency between hazards can be introduced already with comparatively simple methods and are an of import measure towards an integrated hazard position.

Based on the structured hazard information gathered and the integrated position on all relevant hazards, extenuation steps and implemented controls, the hazard director is able to bring forth hazard studies harmonizing to the demand of any type of direction degree.

2b )

There are a figure of elements involved in the development and nidation of operational hazards. They could be divided into Pre-handover activities and post-handover activities. The undermentioned duties should be worked among the undertaking patron, edifice proprietors, contractors and care suppliers.

Sing Pre-handover activities:

First, developing commissioning plan which including the calibrating, proving and running of constructing systems, services and equipment to guarantee the edifice is ready for usage. Sometimes, the manufacturer’s representatives may be present on site to authorise the operation of services and equipment. To do certain the services and equipment have been right installed and working. Calibrating the control instruments and systems to guarantee energy preservation and environment conditions are maintained.

Second, reassigning of certification to the client is involved in the development and execution of operational hazards. For illustration, in footings of edifice service, the edifice certification may include: statutory authorization licenses and blessings, including progressive edifice certifier blessings. Supplying works, equipment, services and system information and agendas, including recommendations sing lifecycle costing, “as-built” edifice programs and commissioning informations, service care demands, operation and care manuals covering design and operating parametric quantities, service care agendas, care and cleansing merchandises, tools and trim parts.

Third, the undertaking contractors should help the edifice proprietor or care suppliers to find the edifice care demands.

Forth, develop handover developing plan to familiarise the edifice proprietor and care supplier forces with edifice equipment and systems. It is a good pattern as preparation Sessionss coordination could use the expertness of the design and building squads such as subcontractors. Effective preparation will allow the edifice users and proprietors obtaining cognition to pull off the edifice and its fixtures, fit-outs, equipment, services and systems. The preparation contents may include occupational instructions and coincide with the handover of edifice certification.

Sing Post- handover activities:

First, place outstanding defects and rectify all outstanding defects prior to concluding completion. If defects or skips are identified by the edifice proprietor after concluding completion.

Second, monitoring care and update edifice plus records is involved in the nidation of operational hazards. Most edifice contracts have a defects liability period, typically for 12 months from the practical completion. Therefore, care activity should be monitored and care records should be continually updated to reflect any new defects and rectification plants. And these records should be added into a defects study, including the inside informations of care activities undertaken.

The certification of concluding completion confirms that all contractual demands have been met, including the rectification or credence of all outstanding defects and attending to all skips.

Forth, undertaking files and histories are to be closed which allow easy auditing in the hereafter. Significant records created or received by the design and building squad must be sorted, indexed and recorded to make an auditable undertaking trail. Care must be taken to hive away all fiscal records firmly. Undertake concluding completion review to guarantee satisfactory rectification of all outstanding defects.

Last but non least, update and maintain plus registry and other relevant plus direction systems.

Problem 3

3a )

Operating temperatures

The electrical energy produced by biomass gasification CHP workss can be consumed straight or injected into the web. The production of thermic energy can be specified at below:

High-temperature heat ( steam or thermic oil, up to 200° C ) applies for industries which consume heat.

Low-temperature heat ( hot H2O at 90-95° C ) applies for industries which consume heat, urban heating webs by infirmaries, schools, authorities organic structures, swimming pools, and industries linked to the wood sector that have co-products and thermic energy demands.

Cost

The capital costs of the biomass CHP procedures are much higher than fossil fuel fired CHP systems. Small-scale biomass CHP is undergoing tests in the UK. Biomass CHP offers a C salvaging potency for big sites ( e.g. over 20 MWe ) . At these graduated tables, biomass CHP will typically utilize steam turbines linked to territory warming.

Environmental ordinance / considerations

To use biomass CHP, several affairs should be considered. Supply a suited supply concatenation for biomass fuel. The site entree for big lorries presenting the fuel and storage infinite for the fuel. The path and mechanism to transport fuel from the shop to the boiler and the works room infinite around the boiler for cleansing.

Integration into the edifice technology system

Constructing systems are normally connected to the web via a heat money changer. Whilst there is some sum of thermic loss from the heat distribution substructure, the collection of little heat tonss from single edifices into a individual big burden allows the usage of big graduated table heat engineerings.

3b )

A territory heating strategy comprises a web of insulated pipes used to present heat, in the signifier of hot H2O or steam, from the point of coevals to an terminal user. District heating webs provide the agencies to transport heat expeditiously. They can presently be built up to around 30km from bring forthing works and distribution webs can be 100s of kilometres long. The development of the territory warming strategy is benefit to the community include avoided costs of energy, through the usage of excess and wasted heat energy, and decreased investing in single family or edifice warming equipment.Problem 4

4a )

CBM is a short signifier Condition Based Maintenance. It is a care scheme that adopted the existent status of the plus to make up one’s mind what care needs to be done. It acts as a status monitoring since it provides an instantaneous indicant of a machine’s status, guaranting critical systems maintained in top status and descry the upcoming of works failure. More, it helps better the conventional care government by measuring declarative parametric quantities of works status such as temperature, quiver, oil status, power quality.

CBM is a extremely effectual care scheme which benefits to safety and dependability nature industries such as aircraft industry, semiconducting material fabrication, atomic, oil and power etc. The advantages illustrations are stated as followers:

First, it enhances fault sensing in many works points. Second, it reduces failure rates, labour clip and fix budgets. Third, by transporting out the CBM, it additions the greater apprehension of works public presentation, and therefore improves the energy efficiency and worker safety.

4b )

As mentioned in 4a ) , there are a batch of benefits by following CBM. Below are the five different CBM methods illustrations which would assist heighten fault sensing in works points and cut down their failure rates.

First, acoustic emanation monitoring which monitoring defect the of course happening high frequence construction borne elastic moving ridges which are produced in stuffs under some signifier of emphasis. Acoustic emanations are the emphasis waves mensurating in dubnium at high frequence 20kHz to 1 MHz. The instrument is normally used to listen and mensurate the acoustic signals emanating from points such as pump’s bearing to specify the status with the works during it operation. It has a good signal to resound ratio and is non affected by background noise.

Second, Vibration analysis which forecast the status for most machines with traveling parts and all revolving machinery has a grade of quiver due to troubles in equilibrating the moving parts. For illustration, bearing debasement and misalignment, to measure works status to heighten mistake sensing and cut down failure rates.

It measured in dubnium at lower frequence scope of 100Hz to 10KHz. When mistakes begin to look in works points, the normal quivers begin to demo marks of alteration. When these quiver measurings are “trended” over a period of clip, the alteration in the works conditions can be seen as a graphical representation. It can bespeak when lubrication is required, whether the lubrication has been successful and the status of bearings. Furthermore, any misalignment, loose constituents and other jobs that cause the machine to vibrate can be detected, giving care staff the opportunity to stop mistakes and maximize the effectivity of these undertakings and their clip.

Third, application of Ultrasonic thickness proving utilizations complex electronic equipment to bring forth and observe contemplations of supersonic quivers from interfaces between stuffs. Any stuff that transmits mechanical quivers can be tested.

It is the best method in footings of cost-effectiveness and the ability to observe abnormalities in a metallic system. For illustration, it can read its thickness by merely touching the steel with the measurement caput. Contact is normally assured by first taking seeable corrosion graduated table and so using crude oil jelly or another couplant before pressing the investigation against metal. It could observe the happening of roughness and clefts both internally and externally ensuing from corrosion, microbic and chemical taint and general wear and tear. Therefore, it avoids the possibilities of leaking and possible failure of critical systems. More significantly, the testing is used to inspect metal to find quality and safety without destructing or compromising its unity.

Forth, Thermography could be used to measure works status by obtaining temperature observations of edifice service pant. The divergence in temperature at which peculiar pieces of works operate is frequently declarative of works status. The radiation emitted from the surface of an object is a map of the object temperature with the infrared component of the radiation being measured and converted into an tantamount temperature. The thermic image is constructed from a battalion of point measurings. And the point temperature values are represented on a Grey or color graduated table.

Last, Lubricant and unstable analysis. Microbes can bring on corrosion of steel and non-ferrous metals or they can speed up normal electro-chemical corrosion processes. This mechanism can be occurred straight or indirectly. The analysis will uncover things like oil taint, incorrect fill degrees, every bit good as a dislocation or debasement of the lubricant’s composing. The process is performed by taking a little sample of the lubricator from the machine in inquiry and directing it to laboratory for aassessment of the presence of the being.

1